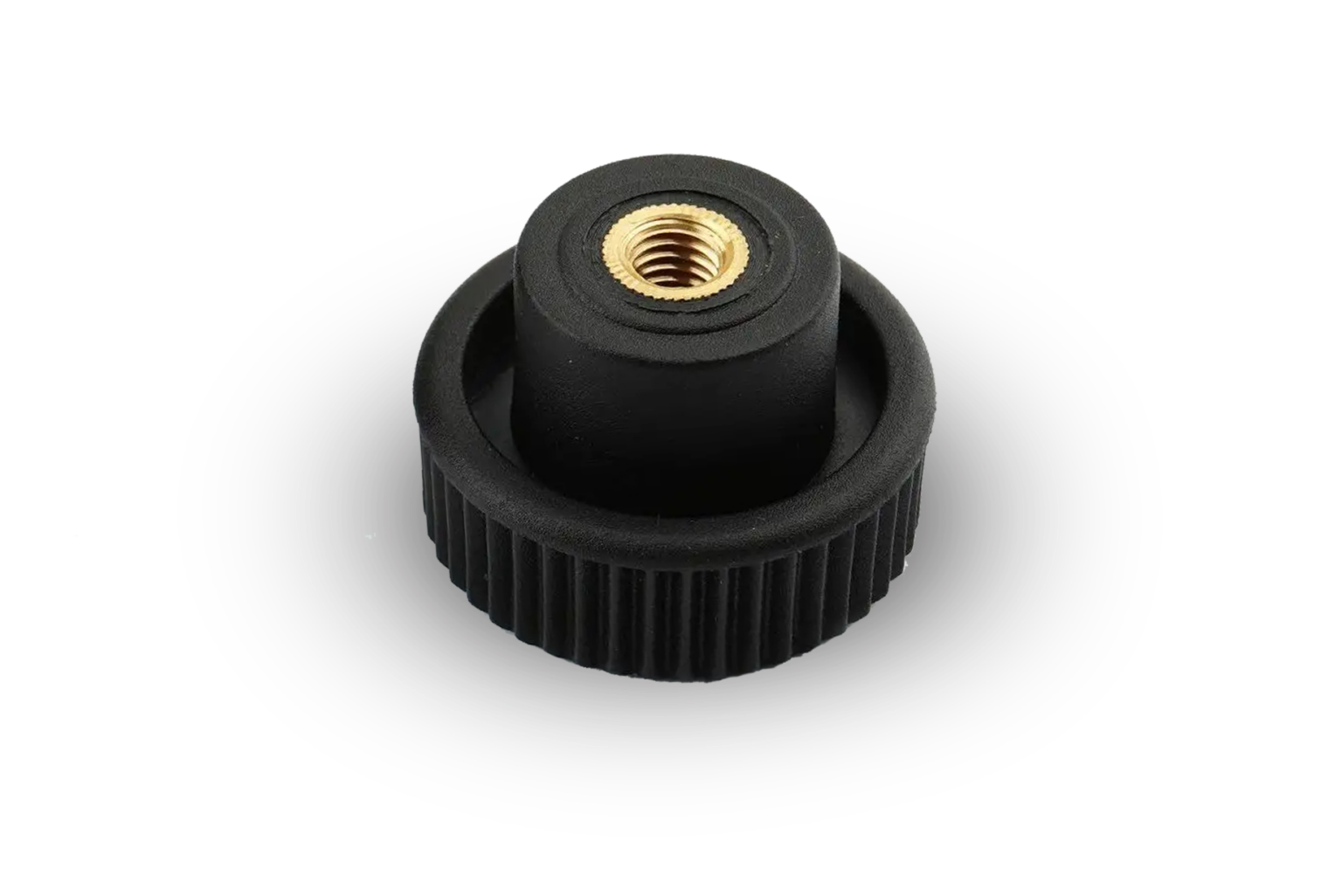

Insert molding is a precision manufacturing process that involves inserting a metal or plastic component into a mold cavity before plastic material is injected. This technique allows for the creation of complex and intricate parts with enhanced strength and durability. At the core of insert molding services are the advanced techniques and capabilities that enable manufacturers to produce high-quality components for a wide range of industries.

Custom Mold Design for Optimal Performance

Comprehensive insert molding solutions encompass a variety of techniques and processes that are designed to deliver superior results. One key aspect of insert molding is the ability to customize the mold design to accommodate the unique requirements of each component. This customization ensures a perfect fit and optimal performance of the finished part. By incorporating advanced design software and cutting-edge technology, manufacturers can create molds that are tailored to the specific needs of their customers.

Advanced Material Selection and Processing

In addition to custom mold design, insert molding services also utilize advanced material selection and processing techniques to achieve superior results. By carefully selecting the right materials for both the insert and the molding material, manufacturers can create parts that are not only durable and reliable but also cost-effective. With a wide range of materials available, including metals, plastics, and composites, insert molding offers endless possibilities for creating components that meet the exact specifications of the customer.

Integrating Multiple Components for Complex Assemblies

Another key aspect of comprehensive insert molding solutions is the ability to integrate multiple components into a single part. By incorporating various inserts and components into a single mold cavity, manufacturers can create complex assemblies in one seamless operation. This not only reduces production time and costs but also ensures the durability and reliability of the finished part. By using advanced tooling and automation techniques, manufacturers can streamline the process of insert molding and achieve consistent results with minimal waste.

Quality Control and Inspection for Guaranteed Excellence

Furthermore, insert molding services include advanced quality control and inspection processes to guarantee the integrity and performance of each part. By implementing stringent quality standards and rigorous testing procedures, manufacturers can ensure that every component meets the highest standards of excellence. With state-of-the-art inspection equipment and skilled technicians, manufacturers can identify any defects or inconsistencies in the manufacturing process and take corrective action to address them promptly.

Conclusion: Delivering Superior Results with Comprehensive Insert Molding Solutions

Overall, comprehensive insert molding solutions offer a range of advanced techniques and capabilities that are essential for achieving superior results in manufacturing. By customizing mold designs, selecting the right materials, integrating multiple components, and implementing strict quality control measures, manufacturers can produce high-quality parts that meet the exact requirements of their customers. With precision insert molding services, manufacturers can enhance the efficiency, performance, and reliability of their manufacturing processes and deliver custom solutions that exceed expectations