In the manufacturing industry, custom overmolding solutions have become increasingly popular for enhancing the functionality and aesthetics of products. With advancements in technology and materials, companies are now able to create complex designs and intricate patterns that were once thought to be impossible. Overmolding is the process of adding a layer of material over an existing part to improve its performance and appearance. This technique is commonly used in the production of electronics, automotive components, and medical devices.

Enhancing Product Aesthetics with Custom Overmolding

One of the key benefits of custom overmolding solutions is the ability to create products with a unique and personalized look. By using different colors, textures, and materials, manufacturers can achieve a wide range of visual effects that help their products stand out in a competitive market. This not only attracts consumers but also adds value to the product, ultimately leading to increased sales and brand recognition.

Improving Product Functionality with Overmolding

In addition to aesthetics, overmolding also plays a crucial role in enhancing the functionality of products. By using materials with specific properties, such as durability, flexibility, or impact resistance, manufacturers can improve the performance and longevity of their products. For example, overmolding can be used to create non-slip grips on tools, shock-absorbing bumpers on electronics, or water-resistant seals on outdoor equipment. These added features not only improve the user experience but also increase the overall reliability and safety of the product.

Innovative Approaches for Complex Manufacturing Needs

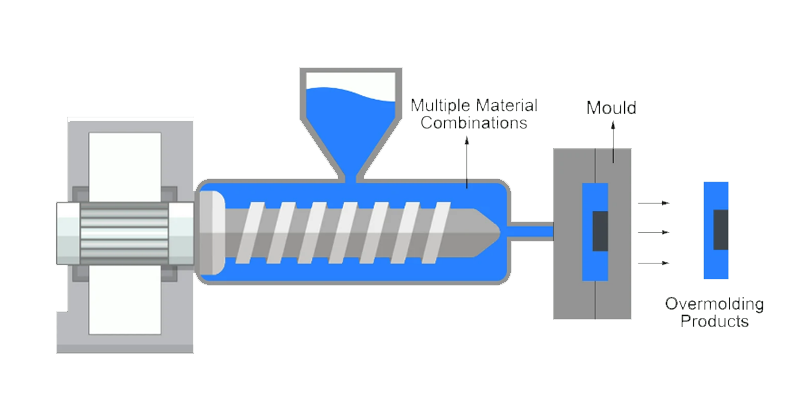

When it comes to complex manufacturing needs, custom overmolding solutions offer innovative approaches that traditional manufacturing methods cannot replicate. By using advanced techniques such as insert molding, multi-shot molding, or micro-molding, manufacturers can create intricate designs with multiple layers and materials. This allows for greater design flexibility and precision, enabling companies to produce products that meet the specific requirements of their customers.

Combining Materials for Enhanced Product Performance

Another advantage of custom overmolding solutions is the ability to combine different materials with varying properties. For example, manufacturers can use a soft and flexible material for the outer layer of a product to provide comfort and grip, while using a rigid material for the inner layer to provide structural support and durability. This combination of materials allows for a more versatile and functional product that can adapt to different usage scenarios and environments.

Conclusion: The Benefits of Custom Overmolding Solutions

Overall, custom overmolding solutions offer a unique and innovative approach to manufacturing that can help companies differentiate themselves in a competitive market. By enhancing both the function and aesthetics of their products, manufacturers can attract more customers, increase sales, and build a strong brand reputation. With advancements in technology and materials, the possibilities for custom overmolding are endless, making it an indispensable tool for companies looking to stay ahead of the curve in today’s fast-paced market.