Blow molding has come a long way since its inception in the early 20th century. Over the years, advancements in technology have revolutionized the manufacturing process, making it more efficient, cost-effective, and environmentally friendly. In this section, we will explore the evolution of blow molding technology, including key trends and innovations that have shaped the industry today.

The Shift Towards Sustainable Practices

One of the most significant trends in blow molding technology is the shift towards more sustainable practices. With increasing awareness of environmental issues, manufacturers are increasingly looking for ways to reduce their carbon footprint and minimize waste. As a result, there has been a growing emphasis on using recycled materials in the manufacturing process. By incorporating recycled plastics into their products, manufacturers can reduce their reliance on virgin materials and help to combat the growing problem of plastic pollution.

Improving Energy Efficiency

In addition to using recycled materials, manufacturers are also exploring new ways to make the blow molding process more energy-efficient. Advances in machinery and equipment have made it possible to produce high-quality products with less energy consumption, resulting in lower production costs and reduced environmental impact. By optimizing the manufacturing process, companies can achieve significant savings in both energy and resources, while also improving the overall quality of their products.

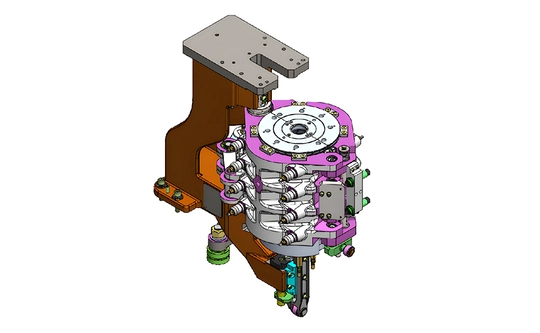

The Rise of Automation and Robotics

Another key trend in Blow Molding Machine Supplier is the increasing use of automation and robotics in the manufacturing process. By automating various stages of production, manufacturers can improve efficiency, reduce labor costs, and enhance product quality. Automated systems can perform tasks such as mold changing, part removal, and quality control with greater speed and precision than manual labor, resulting in higher productivity and lower production costs.

Advances in Mold Design and Manufacturing

Additionally, advancements in mold design and manufacturing have played a significant role in shaping the evolution of blow molding technology. By using computer-aided design (CAD) software and advanced machining techniques, manufacturers can create complex molds with greater precision and efficiency than ever before. This has enabled companies to produce more intricate and customized products, while also reducing lead times and improving overall production efficiency.

New Materials and Additives

Furthermore, the adoption of new materials and additives has also been a key innovation in the blow molding industry. Companies are increasingly experimenting with different types of plastics, additives, and additives to create products that are more durable, lightweight, and cost-effective. By incorporating innovative materials into their products, manufacturers can differentiate themselves in the market and meet the evolving demands of customers for high-quality and environmentally friendly products.

Conclusion

In summary, the evolution of blow molding technology has been driven by a combination of sustainability, efficiency, automation, mold design, and materials innovation. These trends and innovations have revolutionized the manufacturing process, enabling companies to produce high-quality products with greater speed, precision, and cost-effectiveness than ever before. As the industry continues to evolve, we can expect to see even more exciting developments that will further enhance the capabilities and benefits of blow molding technology.